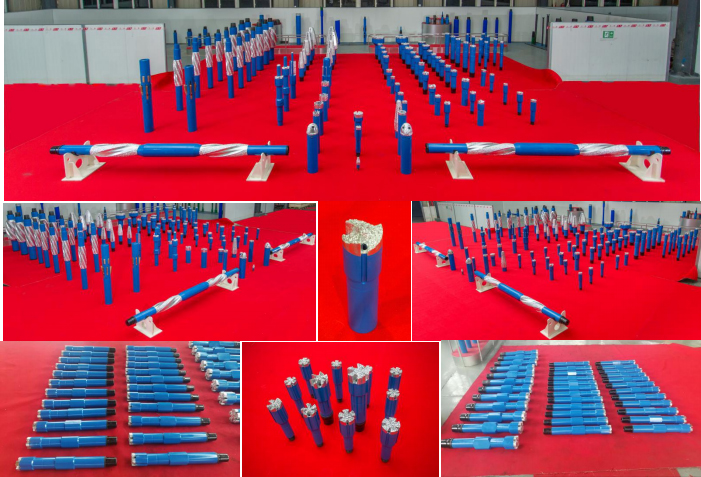

Imikhiqizo

Amathuluzi Okugaya I-Downhole Asebenza Kakhulu

Impahla Yomkhiqizo

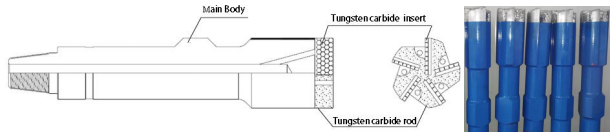

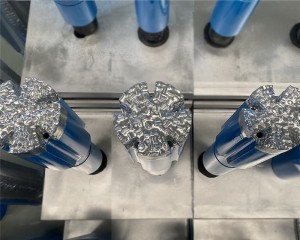

Thatha izicathulo zokugaya phansi njengesibonelo:

Umzimba oyinhloko wamukela i-high-performance alloy steel(4145H) ukuze kuqinisekiswe ukusebenza okushelelayo nokusebenza kahle ngaphansi kwengcindezi yokumba ehlukahlukene kanye nesimo sesivinini sokujikeleza. Ngaleso sikhathi, sisebenzisa i-tungsten carbide yezinga eliphezulu ukufeza ukugaya okusheshayo. I-Stabilizer nesiketi sangaphandle se-junk mill kanye ne-taper mill ingaklanywa njengesidingo.

Faka i-tungsten carbide

·I-Superloy

Isigcwalisi esihle sekhabe, izintambo kanye nezigayo ze-taper.

Ukubuya okuhle kuma-junk Mills.

Ibanga elibanzi losayizi elitholakalayo.

Iningi elimangelengele.

· Metal Muncher

Igaya ngokushesha kunamathuluzi okugaya avamile.

Yehlisa ingcindezi yokumba edingekayo ngenkathi igaywa.

Ishiya ukusikeka okushelelayo ngaphandle kwezindebe ukuze imfucumfucu ilenge.

Ikhiqiza imfucumfucu enosayizi ofanayo.

Ukusika insimbi esikhundleni sokuyigaya.

· I-Opti-cut

Imfucumfucu emincane.

I-ROP esheshayo.

Impilo ende.

Ingcindezi ephansi kanye nezidingo zetorque.

Amaphoyinti okusika ayi-16 kanye nemiphetho yokusika eyi-8 kumsiki ngamunye.

Isigaba somkhiqizo

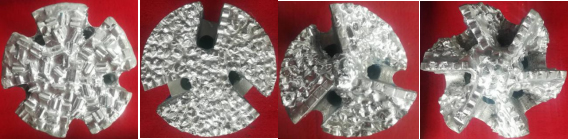

I-Concave/Flat/Blade Bottom junk mill

Isetshenziselwa ukugaya, ikhoni, i-diameter gauge, amazinyo okubamba, ipayipi lokugeza, ithuluzi lokubhoboza ithuluzi, izesekeli zepompo yomthombo ojulile, umpakishi, umsabalalisi wamanzi namanye amathuluzi okubhola amade.

I-Petrozhr junk mill iyatholakala ekucushweni okuhlukahlukene kanye namajometri. Ubunjiniyela bethu bemishini ethuthukisiwe kanye nemishini yokushisela enolwazi iqinisekisa ukwakheka okungaguquguquki futhi okuhlala isikhathi eside kuzo zonke izigayo ezingafuneki.

Ithebhu. 1 Ipharamitha yesigayo se-Flat/Concave/Blade Bottom

| I-Borehole Dia. I-Mill Shoe OD Ubude obunconyiwe (mm) (mm) Uchungechunge lwe-Screw (mm) | PN Isicaba | PN I-Concave | PN I-bladed |

| 95.2- 101.6 89 2-3/8REG 250 | I-JM089FX | I-JM089CX | I-JM089BX |

| 107.9- 114.3 97 2-3/8REG 250 | I-JM097FX | I-JM097CX | I-JM097BX |

| 117.5- 127 110 2-7/8REG 250 | I-JM110FX | I-JM110CX | I-JM110BX |

| 130- 139.7 121 2-7/8REG 250 | I-JM121FX | I-JM121CX | I-JM121BX |

| 142.9- 152.4 130 2-7/8REG 250 | I-JM130FX | I-JM130CX | I-JM130BX |

| 155.6- 165. 1 140 3- 1/2REG 250 | I-JM140FX | I-JM140CX | I-JM140BX |

| 168- 187.3 156 3- 1/2REG 250 | I-JM156FX | I-JM156CX | I-JM156BX |

| 190.5-209.5 178 3- 1/2REG 250 | I-JM178FX | I-JM178CX | I-JM178BX |

| 212.7-241.3 200 4- 1/2REG 250 | I-JM200FX | I-JM200CX | I-JM200BX |

| 244.5-269.9 232 4- 1/2REG 250 | I-JM232FX | I-JM232CX | I-JM232BX |

| 273-295.3 257 6-5/8REG 250 | I-JM257FX | I-JM257CX | I-JM257BX |

| 298.5-317.5 279 6-5/8REG 250 | I-JM279FX | I-JM279CX | I-JM279BX |

| 320.6-346. 1 295 6-5/8REG 250 | I-JM295FX | I-JM295CX | I-JM295BX |

| 349.3-406.4 330 6-5/8REG 250 | I-JM330FX | I-JM330CX | I-JM330BX |

| 406.4-444.5 381 6-5/8REG 250 | I-JM381FX | I-JM381CX | I-JM381BX |

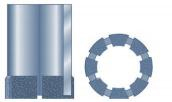

I-Rotary Shoe

Isicathulo esijikelezayo sithatha impahla ye-carbide ngaphakathi kwesilinda ukuze isike inhlanzi engaphezulu ngokujikelezayo, futhi kancane kancane ilungise ingxenye engaphezulu yenhlanzi eyonakele ibe yindingiliza, efana neshubhu, i-casing body, njll.

[Qaphela: Ngenxa yokuthi ububanzi bezinyo lokugaya elingaphakathi lesicathulo esijikelezayo bukhulu, i-torque ehlehlayo inkulu, ngakho-ke ukucindezela okuphansi kanye nemodi yokujikeleza kancane kufanele yamukelwe ekusetshenzisweni kwesicathulo esijikelezayo. Ngokuvamile, ukucindezela kokubhola akufanele kudlule ku-10 KN futhi isivinini sokujikeleza akufanele sidlule ku-50 r/min.]

Uhlobo A

Sika insimbi, usimende kanye nokwakheka.

Ukusika ku-OD nangaphansi.

Uhlobo B

Ukusika insimbi lapho imvume incane.

Ukusika ku-ID nangaphansi.

Uhlobo C

Sika ukwakheka.

Ukusika ku-OD nangaphansi.

Uhlobo D

Sika ukwakheka kanye nezinhlanzi ngesikhathi esifanayo.

Ukusika ku-ID, OD nangaphansi.

Ithebhu.2 Ipharamitha yezicathulo ezijikelezayo

| I-Casing/Wellbore Dia. | I-Rotary shoe OD (mm) | Isicathulo esijikelezayo Ubude (mm) | Kunconywe Uchungechunge Lwe-Screw | PN I-Rotary Shoe | |

| 4in | 101.6mm | 95 400 | I-FJWP | TXX095 | |

| 5- 1/2in | 139.7mm | 114 500 | I-FJWP | TXX114 | |

| 5-3/8in | 146.05mm | 118 500 | I-FJWP | TXX118 | |

| 6-5/8in | 168.28mm | 136 425 | I-FJWP | TXX135 | |

| 7in | 177.8mm | 152 450 | I-FJWP | TXX152 | |

| 7-5/8in | 193.68mm | 160 450 | I-FJWP | TXX160 | |

| 8-5/8in | 219. 1mm | 185 550 | I-FJWP | TXX185 | |

| 12- 1/4in 311. 15mm | 203 450 | I-FJWP | TXX203 | ||

| 15-5/8in 396.88mm | 298 450 | I-FJWP | TXX298 | ||

| 20in | 508mm | 406 450 | I-FJWP | TXX406 | |

I-Taper Mill

I-taper mill ikhipha imikhawulo, i-casing egoqiwe kanye nezingxenye ze-liner kanye namafasitela e-deburr whipstock kanye ne-casing. Ingxenye ephansi ye-taper mill, nobubanzi bayo obuncane bungena endaweni egoqiwe ye-casing kanye no-liner. Bese imiphetho ye-reamer egoqekile ukuze isuse ingxenye engaphansi ukuze igcwale. ububanzi bokugaya.

I-taper mill iqukethe umzimba oyi-conical kanye ne-tungsten carbide. I-taper yomzimba ingama-degrees angu-30, i-cone imise okwephiko, futhi ingaphezulu liqinile noma lifaka i-tungsten carbide.

Ithebhu.3 Ipharamitha ye-taper mill

| Umgodi wamanzi Dia. I-Taper isigayo OD Kunconyiwe Ubude (mm) (mm)Isikulufu Uchungechunge(mm) | P.N. I-Taper isigayo | ||

| 95- 101.6 | 89 | 2-3/8REG 300 | XZ089 |

| 107.9- 114.3 97 2-3/8REG 300 | XZ097 | ||

| 117.5- 127.0 110 2-7/8REG 300 | I-XZ110 | ||

| 130- 139.7 121 2-7/8REG 300 | XZ121 | ||

| 142.9- 152.4 130 2-7/8REG 300 | I-XZ130 | ||

| 155.6- 165. 1 140 3- 1/2REG 300 | I-XZ140 | ||

| 168- 187.3 156 3- 1/2REG 300 | I-XZ156 | ||

| 190.5-209.5 178 3- 1/2REG 300 | XZ178 | ||

| 212.7-241.3 200 4- 1/2REG 300 | XZ200 | ||

| 244.5-269.9 232 6-5/8REG 350 | XZ232 | ||

| 273-295.3 257 6-5/8REG 350 | XZ257 | ||

| 298.5-317.5 279 6-5/8REG 350 | XZ279 | ||

| 320.6-346. 1 295 6-5/8REG 350 | XZ295 | ||

| 349.3-406.4 330 6-5/8REG 350 | I-XZ330 | ||

| 406.4-444.5 381 6-5/8REG 350 | XZ381 | ||

I-Watermelon String Mill

Isicathulo sentambo ye-Watermelon singelinye lamathuluzi okugaya ekusebenzeni kokuchezukisa. Isetshenziselwa ukulungisa i-casing, ukulungisa kabusha kanye nokuvula iziteshi. Ngokuvamile isetshenziswa ngokushesha ngemva kokuvula amafasitela. Unqenqema lokugaya (indawo yokusebenza) yesigayo sekhabe luthinta udonga lwe-borehole, futhi ukuphela konqenqema ngalunye kuklanywe njengekhoni. Lapho iwindi livulwa, isigayo sekhabe singanweba iwindi ukusuka phezulu futhi sisuse ukukala kanye nama-burrs asele odongeni lwamapayipi ngesikhathi sokusika kokuqala.

Ithebhu.4 Ipharamitha yochungechunge lwe-Watermelon yokugaya

| I-Borehole Dia. Isikulufu (mm/in ) Uchungechunge | Indawo Yokusebenzela OD (mm/in) | Ubude bendawo yokusebenza (mm/in) | Ubude obuphelele (mm/in) | PN |

| 139.7 (5- 1/2) NC 26 112 (4-7/ 16) 600 (23-5/8) | 1130 (44) | XGMX112 | ||

| 139.7 (5- 1/2) NC 26 116 (4-9/ 16) 600 (23-5/8) | 1130 (44) | XGMX116 | ||

| 139.7 (5- 1/2) NC 26 118 (4-5/8) 600 (23-5/8) | 1130 (44) | XGMX118 | ||

| 139.7 (5- 1/2) NC 31 120 (4-3/4) 600 (23-5/8) | 1280 (50) | XGMX120 | ||

| 146.0 (5-3/4) NC 31 124 (4-7/8) 600 (23-5/8) | 1280 (50) | XGMX124 | ||

| 168.3 (6-5/8) NC 31 142 (5-9/ 16) 600 (23-5/8) | 1280 (50) | XGMX142 | ||

| 177.8 (7) NC 31 151 (5- 15/ 16) 600 (23-5/8) | 1280 (50) | XGMX151 | ||

Isigayo somshayeli

Imishini yokushayela idizayinelwe i-milling casing, i-liner, isicathulo esijikelezayo noma ishubhu enkulu ye-ID. Izindwani zokusika ezigqoke ngezinto ezisezingeni eliphezulu ze-tungsten carbide zenza i-Petrozhr pilot mill ingafinyelela ukungena ngokushesha ngokugqoka okuncane.Imfucumfucu yokusika encane negobile kulula ukuyisusa. Futhi isiphetho somshayeli sisetshenziselwa ukuzinza ku-ID wento egaywayo.

Ipharamitha ye-Tab.5 Pilot mill

| Umgodi wamanzi Dia. (mm) | Isikulufu Uchungechunge | Indawo Yokusebenzela OD (mm) | I-blade yokusika Ubude (mm) | Ubude bendawo yomshayeli (mm) | PN |

| 153 2 3/8REG | 130 200 | ≧45 | I-LYMX130 | ||

| 165 2 3/8REG | 140 200 | ≧45 | I-LYMX140 | ||

| 187 3 1/2REG | 156 200 | ≧55 | I-LYMX156 | ||

| 210 4 1/2REG | 178 200 | ≧55 | I-LYMX178 | ||

| 241 4 1/2REG | 200 200 | ≧55 | I-LYMX200 | ||

| 270 4 1/2REG | 232 200 | ≧55 | I-LYMX232 | ||

| 295 6 5/8REG | 257 250 | ≧55 | I-LYMX257 | ||

| 317 6 5/8REG | 279 250 | ≧55 | I-LYMX279 | ||

| 346 6 5/8REG | 295 300 | ≧55 | I-LYMX295 | ||

| 406 6 5/8REG | 330 300 | ≧55 | I-LYMX330 | ||

| 445 6 5/8REG | 331 300 | ≧55 | I-LYMX331 | ||

Ishadi lesicelo se-Tungsten carbide

| Isicelo esinconyiwe | I-Superloy | I-Opti-cut | Metal-muncher | Metal-muncher noSuperloy |

| Washover imbobo evulekile | √ | √ | ||

| Ipayipi lokubhoboza i-washover | √ | |||

| Washover gravel pack | √ | √ | ||

| I-washover liner trim | √ | |||

| Iphakethe le-washover | √ | |||

| Ukugaya i-Poil | √ | |||

| Ukugaywa kwe-Junk okuxekethile | √ | √ | ||

| Ipaki emile noma ipayipi noma i-tubingjunk milling | √ | |||

| Ukugaya ikhabe | √ | |||

| Ukugaya intambo | √ |

Ukudoba Into Izithombe

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141