Ubuchwepheshe bokulawula iphrofayili bomjovo kahle bubhekisa kubuchwepheshe bokulawula ukumuncwa kwamanzi kongqimba oluphakeme lokumuncwa kwamanzi ngendlela yomshini noma yamakhemikhali, okwandisa ukumuncwa kwamanzi kwesendlalelo sokumuncwa kwamanzi aphansi ngokufanele, okwenza umjovo wamanzi uqhubeke ngokulinganayo futhi uthuthukise i-coefficient yokushanela kawoyela. ungqimba.

Kunezindlela zemishini nezindlela zamakhemikhali zokulawula iphrofayili ye-injection Wells. Indlela yokulawula iphrofayili yomshini ngokuyinhloko ukulungisa inani lomjovo wamanzi wesendlalelo ngasinye ngomjovo wamanzi we-stratified, ukuze kufezwe injongo yokulungisa iphrofayili yokumunca.

Enqubweni yokukhiqiza kawoyela negesi Wells, amashubhu angaphansi komhlaba agqwalile futhi agugulwe imithombo edlayo efana ne-hydrogen sulfide, i-carbon dioxide kanye nokwakheka kwamanzi omkhakha wegesi isikhathi eside, okuholela ekunciphiseni kodonga lwamashubhu, ukubhobozwa ngisho nokuphuka.

- 1.UkugqwalaI-Tubing Well Izici

(1) I-coefficient yokucindezela kokubunjwa iphansi, iningi labo liphakathi kuka-0.5 no-0.7, kanti ezinye ziphansi, ngakho-ke akunakwenzeka ukusungula ukujikeleza, okuletha ubunzima obukhulu ekugayeni, ukugaya nokugaya.

(2) Izinga lokugqwala kwamashubhu libi kakhulu, ngokuvamile lifika ku-30% kuya ku-60% (ingxenyana yobuningi), futhi udonga lwamapayipi lugqwalile ngaphakathi nangaphandle.

(3) Amandla wekholomu yepayipi aphansi, ukucindezela kulula "ukunciphisa", futhi phezulu kwezinhlanzi kuvame ukushintsha, ngakho ukuphrinta okuholayo akusizi;

(4) Kunzima ukwenza ibhande ngaphakathi nangaphandle.

2.Isimiso Sokudoba I-Corrosion Tubing

Ngaphezu kwezimiso zokudoba ezivamile, ukudoba ngamashubhu okugqwalile kufanele kulandele lezi zimiso ezilandelayo:

(1) Izimo ezingaphansi komhlaba zicacile, amathuluzi okudoba akhethwa ngokunembile, futhi ubuqotho bendawo engaphezulu yezinhlanzi kanye nezinhlanzi ezingaphansi komhlaba kugcinwa ngangokunokwenzeka;

(2) Ukuphepha kokulawulwa kahle kufanele kuqinisekiswe ngesikhathi sokudoba.

(3) Imisebenzi yokudoba ayikwazi ukwenza inkimbinkimbi isimo esingaphansi komhlaba, noma yiziphi izinyathelo kufanele zibe nendlela yokuphuma, azikwazi ukudoba ngokungenangqondo;

(4)Ayikwazi ukuthikameza umthamo wangempela wokukhiqiza;

(5) Awukwazi ukusebenzisa kalula umshini wokugaya, kodwa awukwazi ukusebenzisa kalula ukugaya izicathulo, ukugwema ukuthi kube nzima kakhulu;

(6) Vimbela ukulimala kwekesi.

3.Corrosion Tubing Izinyathelo Zokudoba

(1) Ukugqwala kweshubhu ngokuqinisekile kuletha ukugqwala kwebhokisi, ngakho-ke kuyadingeka ukuthola nokwahlulela ikhwalithi yebhokisi lamapayipi omthombo, futhi uzame ukugwema ukulimala kwamashubhu nebhokisi.

(2)Ungajahi, yihlele futhi uyihlele kahle. Amashubhu agqwalile ngokusobala ahlukile ekudobeni okujwayelekile kwamashubhu kanye nokubhoboza amapayipi. I-Tubing ayikwazi ukuhlengwa ngendlela efanayo nokudoba amapayipi. Uma kwamukelwa ukudoba okuphoqelelwe kakhulu, amashubhu angase abanjwe ngaphandle kwebhokisi. Ngakho-ke, uma ukukhethwa kwamathuluzi kungenangqondo, kungase kubangele ngaphansi komhlaba okuyinkimbinkimbi, kuletha ubunzima obungenakulinganiswa ekusindiseni kamuva. Ukukhethwa kwamathuluzi okuqala kungcono kakhulu ukuthi ungacabangi amathuluzi anezakhiwo zokugaya, ukugaya nokugaya, ngoba ziyacasula futhi zingase zibhubhise izinhlanzi kanye ne-casing, ziletha ubunzima obuningi.

(3) Izisetshenziswa kumele zithembeke futhi zinembile. Uhlelo lwamabhuleki lomshini wokusebenza lubucayi futhi luthembekile, futhi ukusetshenziswa kwendandatho yokuphakamisa kanye nekheshi kuboshwe ngokuqinile, futhi izinga lomgodi wezintambo liyahlolwa. I-crane, i-turntable kanye ne-wellhead kufanele iphathwe kahle. Ipayipi le-Kelly kufanele liqondiswe, ngemuva kokusetshenziswa alikwazi ukutshekiswa emaphethelweni omshini wokubhoboza; Inkomba yesisindo iyazwela, ithembekile futhi inembile. Amathuluzi kufanele ahlolwe ngokucophelela futhi alebulwe (okungcono ngezithombe) ngaphandle kwezinkinga zekhwalithi. Linganisa ngokucophelela, bala “izikwele ezintathu zibe” (isikwele esiphezulu senhlanzi sibe, hlenga uhlangothi lube, uhlangothi oluphezulu lokusindisa lube), bese umaka

(4)Thola izimo zangaphakathi nezakudala zeshubhu. Umgomo obalulekile wokudoba kufanele uqale ngaphandle kwepayipi likawoyela, uhlole i-annulus yangaphandle yepayipi likawoyela, futhi ngokuvamile ungasebenzisi ukudoba kwangaphakathi (kumapayipi kawoyela agqwalile). Ukukhethwa kwamathuluzi kungenziwa elungiselelwe isilinda sokudoba i-back-off, isilinda sokudoba sefasitela esisuswayo, isilinda sokudoba se-sliding block kanye namanye amathuluzi angalimazi izinhlanzi, ukucindezela okulula nokujika kancane lapho udoba, isisindo esincane akufanele sibe phezulu kakhulu. .

(5)Ngaphezu kwezizathu zokuphepha, ngokuyinhloko kuwukuhlaziywa kokulawulwa kobuchwepheshe, futhi izinto ezihamba phansi neziphumayo kufanele zihlaziywe ngokucophelela, zifakwe umugqa, zihlanganiswe futhi zibuyiselwe, ukuze kuhlaziywe izimo ezingaba khona zemayini.

6 ikhanda kufanele lihlaziywe.

4.I-Corrosion Tubing Amathuluzi Okudoba

1,I-Die Collars

Uhlu olukhulu lwentambo yesifazane yokudoba i-cone taper lungasethwa ku-1:8, okuyi-taper ephindwe kabili yentambo evamile yokudoba i-cone yabesifazane, futhi ubude bentambo yokudoba buyandiswa ngokufanele, futhi ububanzi bokudoba bukhulu kakhulu kune uhla lokudoba lwekhoni evamile yesifazane. Isibonelo, intambo yesifazane i-MZ60 × 125 ubude bentambo yokudoba engu-177.8mm i-520mm, i-taper ingu-1: 8, ububanzi obukhulu bungu-125mm, kanti uhla lokudoba luyi-60 ~ 125mm; Ngemuva kokuphuka kokugqwala kweshubhu okungama-73mm, ukuphuka kweshubhu kuyacindezelwa futhi kukhubazekile, futhi ububanzi be-eksisi ende buvamise ukuba ngu-90~105mm, futhi ubukhulu ngokuvamile abukho ngaphezu kuka-115mm. Lapho udoba, zungeza phansi, uholele isicathulo ezinhlanzini eziwayo, inhlanzi ewayo ibe uhla olukhulu lwama-cones wesifazane, bese uqhubeka ujikeleza phansi ukuze uqedele phezulu kwezinhlanzi zokugqoka nokubamba.

Uhlu olukhulu lwe-Die Collars lusetshenziselwa ukudoba amashubhu agqwalile agugeke kakhulu phezulu kwenhlanzi kodwa ngamandla athile, futhi angahlenga izingcezu eziphukile kanye nemfucumfucu yamashubhu ukuze kuhlanzeke ingaphezulu lenhlanzi, futhi lingahlenga neshubhu eliphelele. , esetshenziswa kabanzi futhi ivikela ngokuphumelelayo phezulu kwezinhlanzi.

2.Block Spears Fishing

I-Block Spears yakhiwe ngomzimba womgqomo, isilayidi nesicathulo somhlahlandlela. Ukuphela kwe-cylinder kuyintambo yangaphakathi, engaxhunywa ku-cylinder ende. Ingaphakathi langaphakathi liyi-conical cavity "nengxenye encane engaphezulu" futhi ama-chute amathathu avulwe ngokulinganayo engxenyeni ephakathi. Ibhulokhi yesilayidi ifakwe ku-chute, ubuso bokugcina bebhulokhi yesilayidi bucutshungulwa ngamazinyo e-radial, futhi ubuso bokugcina obungaphakathi bunomugqa wamazinyo angaphakathi aguquguqukayo. Ngesikhathi sokudoba, isicathulo siholelwa enhlanzini futhi isilinda sokudoba siyehliswa, indawo engaphezulu yenhlanzi iphushelwe phezulu eduze kwe-chute, ingaphezulu lezinhlanzi lidlula endaweni yama-slide, isilinda sokudoba siyaphakanyiswa, futhi i-slide block ihambisana eduze. i-chute yokubamba izinhlanzi futhi uzuze ukudoba.

Ingxenye yokudoba yeBlock kungaba umzimba wepayipi likawoyela noma ukuhlangana kwepayipi likawoyela. Lapho udoba, ukuhlangana kokuqala ngaphansi kwenhlanzi kungadlula kusilayidi ukuze kuqashelwe ukudoba ngokuphakamisa ukuhlanganisa; Kungenza futhi isilayidi sigweme ingxenye engathi sína ye-corrosion deformation yepayipi likawoyela futhi sibambe ingxenye ephelele kakhulu.

I-Block Spears ayikwazi nje ukubona ukudoba ngamashubhu, kodwa futhi ibona ibhande elibuyela emuva lapho ishubhu libhajwe. I-torque ehlehlayo idluliswa ngamazinyo e-radial phezulu kwesilayidi noma ngamazinyo angaphakathi wesilayidi, isilayidi kanye ne-chute. I-sliding block dredge ifanele ukudoba ngamashubhu lapho ukubola kwe-corrosion kungambi kakhulu, futhi izinga layo lempumelelo yokudoba liphezulu.

3.Overshot Nge Slot

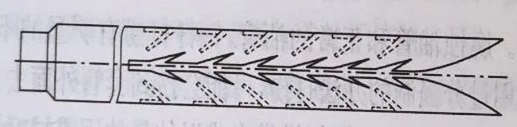

I-overshot ene-slot yenziwe ngomphongolo noma i-casing ye-scrap 8 kuya ku-10m, njengoba kukhonjisiwe kuMfanekiso 1-1. Ukuphela okuphansi kwesigubhu sokudoba kwenziwa uhlobo lwethiphu yepeni kanye nesicathulo somhlahlandlela we-duck-bill, futhi umzimba we-cylinder uvulwa ngokulinganayo ngemigqa eyodwa noma kabili, ngokunwebeka okuhle, ukuvula kalula ukuze kube lula ukwethulwa kwezinhlanzi eziwayo, futhi kulula ukubuyisela isikhundla sokuqala sokugoqa izinhlanzi eziwayo. I-hook yenziwe ngefasitela lokuvula ku-cylinder, i-triangular noma i-trapezoidal, inyakaza, inamandla athile nokunwebeka.

Fig1 Overshot With Slot Umdwebo

Ngemva kokuba inhlanzi ivezwe ezinhlanzini eziwayo, i-bill yedada noma isicathulo somhlahlandlela wepeni sizovuleka ngokwemvelo futhi sehle eduze nodonga lwe-casing. Izinhlanzi eziwayo zizongena engxenyeni yokudoba yombhobho wokudoba ngokusebenzisa isicathulo somhlahlandlela, cindezela ukuqina kwe-hook yokudoba, futhi ngesikhathi esifanayo, vula ingxenye ephukile, uqhubeke unciphisa intambo yepayipi ngaphansi kwengcindezi, futhi inhlanzi ewayo izoba. qhubeka ungene engxenyeni engenhla yomphongolo wokudoba, uphakamise intambo yokudoba, futhi i-hook yokudoba izobambelela emgodini noma ingene emgodini ogqwalile. Noma sekela esinyathelweni sekhola nejoyinti ukuze uzuze ukudoba ngamashubhu okugqwalile.

I-overshot ene-slot ingahlenga ipayipi likawoyela eliphukile kanye nepayipi likawoyela elibheke ohlangothini ngalunye, futhi lingahlenga nepayipi likawoyela eliphukile, imfucumfucu kanye nezinye izibi, lihlanze ingaphezulu lezinhlanzi, futhi lidale izimo zokuhlenga okulandelayo.

4.Ithuluzi Elihlanganisiwe Lokugaya Nokudoba

Ithuluzi lokuhlanganisa lingaqedela ukusebenza okuhlangene kokugaya nokudoba. Izicathulo zokugaya zihlanganiswa nesigubhu sokudonsa amafasitela, isigubhu sokudonsa izintambo zensimbi, isigubhu se-sliding block dredging, i-female cone namanye amathuluzi okudoba, angaqedela umsebenzi wokugaya, ukulungisa izinhlanzi kanye nokudoba. Ukuze kuvikelwe phezulu kwezinhlanzi ngangokunokwenzeka, izicathulo zokugaya zisebenzisa izicathulo ezinkulu zokugaya ububanzi obungaphakathi.

I-cone enkulu ye-casing cone iyithuluzi elisebenzayo lokugqwala kwe-tubing casing. Yakhiwe yisigayo esikhulu sangaphakathi se-diameter casing kanye ne-cone enkulu ye-casing cone. Ama-overshoes amakhulu angaphakathi obubanzi anobubanzi obukhulu bangaphakathi, kulula ukwethula phezulu kwezinhlanzi, futhi ubukhulu bezinhlanzi ezigayiwe buncane; Uhlu olukhulu lwentambo yokudoba i-female cone taper, ububanzi obukhulu bentambo yokudoba bukhulu, bese buncane ngokushesha, phezulu kwenhlanzi ku-cone yesifazane ngokushesha ngemva kokuxhumana nengxenye yokudoba. Ngakho-ke, uhla olukhulu lwama-cones wesifazane olugayiwe lungavikela phezulu kwezinhlanzi ngezinga elikhulu, futhi lungaqedela umsebenzi wokudoba.

Isikhathi sokuthumela: Jul-10-2024

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141