Ipulaki yebhuloho elincibilikayo lenziwe ngezinto ezintsha, ezisetshenziswa njengethuluzi lesikhashana lokuhlukanisa i-wellbore ukuze kuqhekeke umthombo ovundlile kanye nokulungisa kabusha.

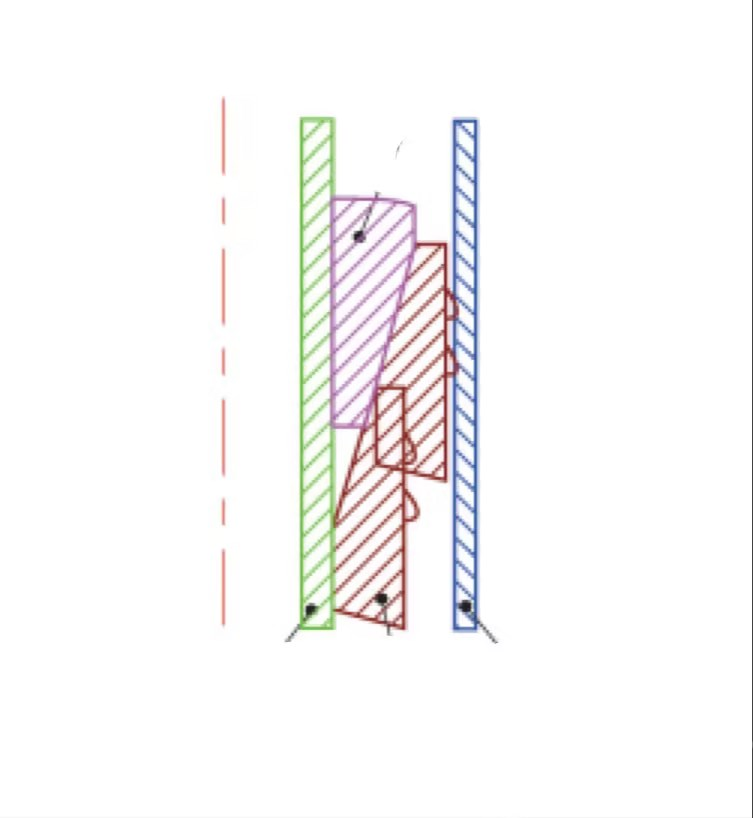

Ipulaki yebhuloho elincibilikayo lakhiwe ngokuyinhloko izingxenye ezi-3: umzimba wepulaki yebhuloho, indlela yokubambelela kanye nezimpawu. Umzimba wepulaki yebhuloho wenziwe ngezinto ezincibilika ezinamandla aphezulu, okuhlanganisa ishubhu eliphakathi nendawo, ikhoni, iringi yokuvikela namajoyinti. I-anchoring mechanism yenziwe ngezinto ezihlakazekayo njengesithwali, futhi indawo engaphezulu iphathwa nge-alloy powder, izinhlayiya ze-alloy noma izinhlayiya ze-ceramic. Izimpawu ziyirabha ehlakazekayo noma ipulasitiki.

1.Izingxenye zamapulaki ebhuloho ahlukanisekayo

Amapulagi ebhuloho angancibilika enziwe ngokuyinhloko ngamandla aphezulu e-magnesium-aluminium alloy noma i-polymer material processing. Ingxubevange ye-Magnesium-aluminium ngokuyinhloko yakhiwe i-magnesium, enomthamo omncane (cishe u-1.8~2.0g/cm³), futhi ngesikhathi esifanayo, umsebenzi wayo wamakhemikhali uphezulu, ngakho kulula ukuncibilika endaweni enomswakama.

Izinga lokuqedwa kwe-magnesium-aluminium alloy lihlobene kakhulu nokushisa kwe-liquid kanye ne-Cl-concentration, izinga lokushisa eliphakeme, ukuchithwa ngokushesha; ukuphakama kwe-Cl-concentration, ngokushesha ifilimu ye-passivation ebusweni be-alloy ibhubhisa, ngcono ukuqhutshwa kwe-liquid, ngokushesha izinga lokuqedwa.

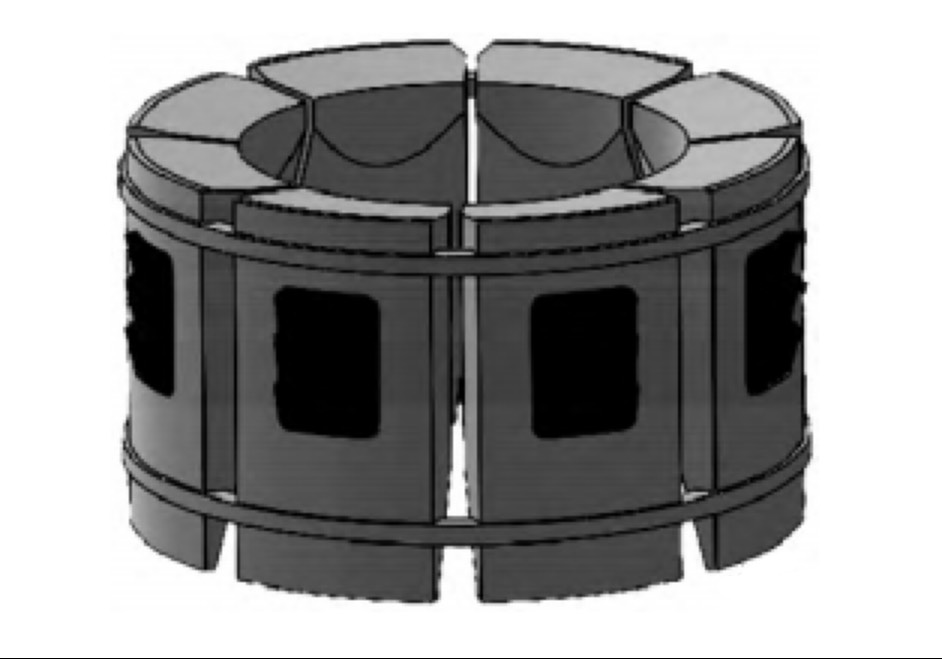

2.Umshini wokunamathisela wepulagi webhuloho ohlukanisekayo

Ithayela lokunamathisela lepulaki lebhuloho elihlakazekayo lihlukile kuthayela wensimbi oxutshiwe ovamile kanye nethayela eliyinhlanganisela, ngaphezu kwesidingo sokuhlinzeka ngamandla okubambelela e-casing athembekile namandla okukhiya isilinda, kodwa futhi kufanele kube nokusebenza okuhle kokuhlakazeka kanye nekhono lokubuyela ekukhishweni.

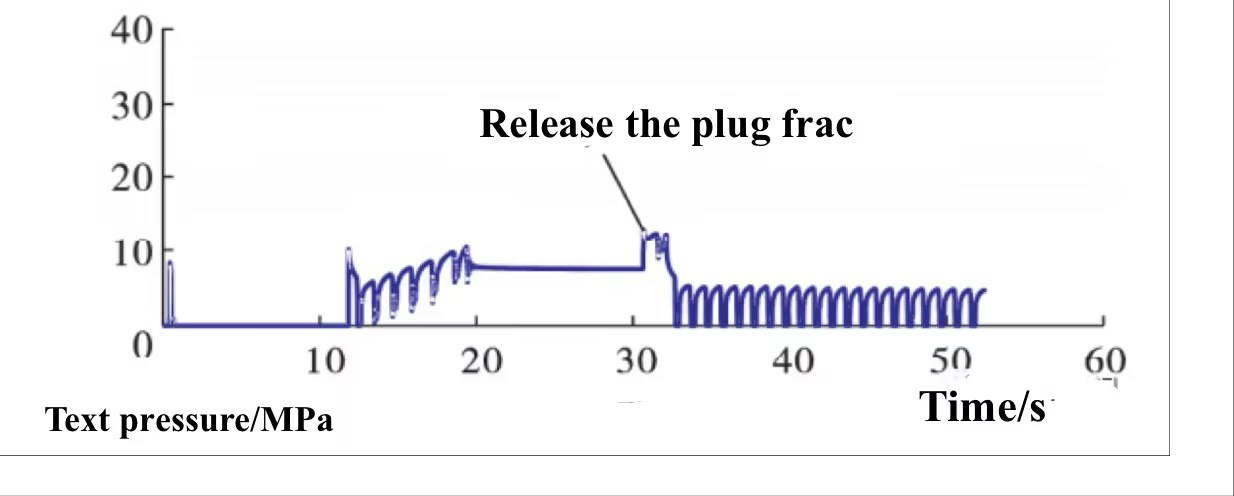

3.I-Dissolvable Bridge Plug Seat Seal Inani Lokukhipha

I-Baker 20 # i-hydraulic seating tool izoba yipulaki yebhuloho ehlakazekayo ihlezi endaweni yamathuluzi ye-casing, inqubo yokuhlola yepulaki yebhuloho nethuluzi lokuhlala ifaniswe kahle, ipulaki yebhuloho ihlaliswe ngempumelelo nesandla esilahlekile, ukuncipha kokucindezela kwesandla okungu-12.3MPa (ukulahlekelwa okulinganako kwamandla esandla angaba ngu-155kN) ijika lesandla elihlezi njengoba kukhonjisiwe esithombeni.

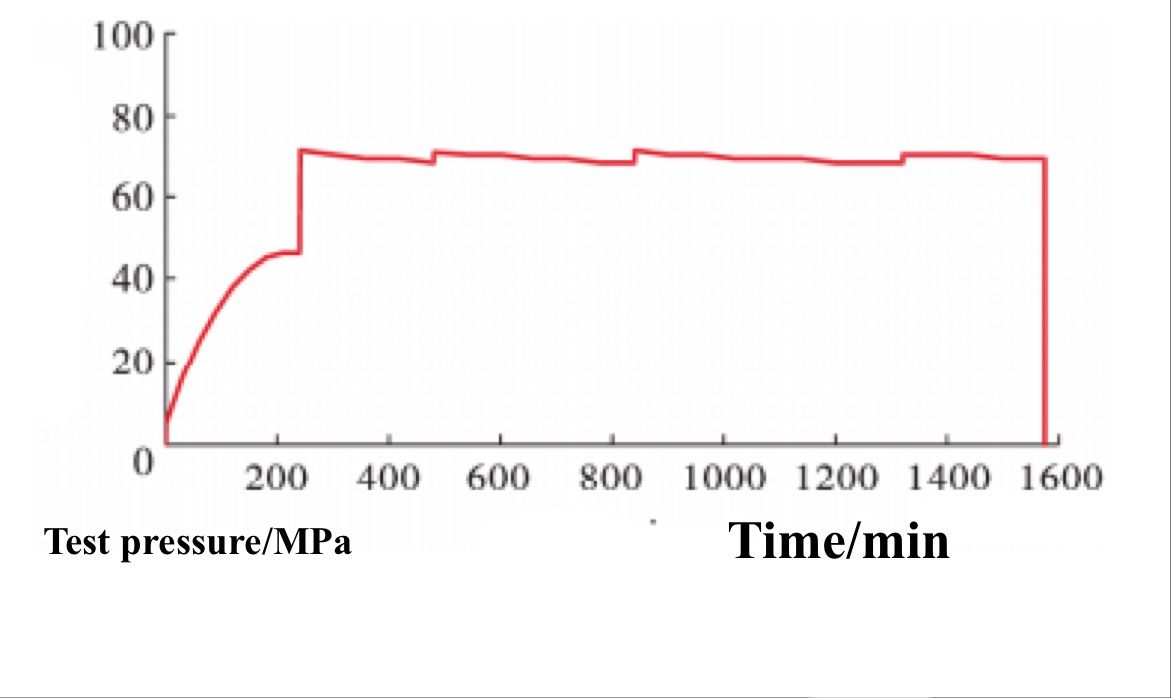

4.Ukucindezela kokuvala ukusebenza kwepulaki yebhuloho ehlakazekayo

Ukuze kuqinisekiswe ukusebenza kokuvalwa kwengcindezi yezinga lokushisa eliphezulu kwepulaki yebhuloho elihlukanisekayo, isisebenzi se-casing safakwa kudivayisi yokuhlola yezinga eliphezulu lokushisa futhi sashisisa kufika ku-93°C. Ngemuva kokuthi izinga lokushisa lizinzile, ingcindezi yanda kancane yaba ngu-70 MPa. Ukucindezela kwaqiniswa amahora angu-24 futhi kwagcinwa imizuzu engu-15. Kukhona ukwehla kwengcindezi okusobala futhi ijika lokuhlola ingcindezi liboniswa esithombeni. Imiphumela yokuhlolwa ibonisa ukuthi ukusebenza kokuvala ngomfutho kwepulaki yebhuloho kungahlangabezana nezidingo zokwakhiwa kwe-fracturing esizeni.

5.Isikhathi sokusebenza sepulaki yebhuloho ehlakazekayo

Umkhawulo wesikhathi sokusebenza isikhawu sesikhathi kusukela lapho ipulaki yebhuloho ifakwa emthonjeni ukuya ekuqhekekeni. Ngokwemodeli ekhona yokwakhiwa kwegesi ye-shale, umkhawulo wesikhathi sokusebenza wepulaki yebhuloho ehlakazeka amahora angama-24, ongahlangabezana nezidingo zokwakhiwa kwemithombo yegesi ye-shale, okungukuthi, kusukela ngesikhathi kufakwa ipulaki yebhuloho elihlakazekayo. emthonjeni Kusukela ngehora, ukwakhiwa kwe-fracturing kungenziwa kungakapheli amahora angama-24. Noma ikuphi ukuhlolwa kokusebenza kwamapulaki ebhuloho ahlakazekayo kungenziwa kubhekiselwa kumkhawulo wesikhathi sokusebenza wamahora angama-24.

Isikhathi sokuthumela: Sep-22-2023

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141