Isakhiwo somthombo sibhekisela ekujuleni kokubhoboza kanye nobubanzi obuncane besigaba somthombo ohambisanayo, inani lezendlalelo zebhokisi, ububanzi nokujula, ukuphakama kukasimende okubuyayo ngaphandle kwesendlalelo ngasinye sebhokisi kanye nembobo engaphansi yokwenziwa.

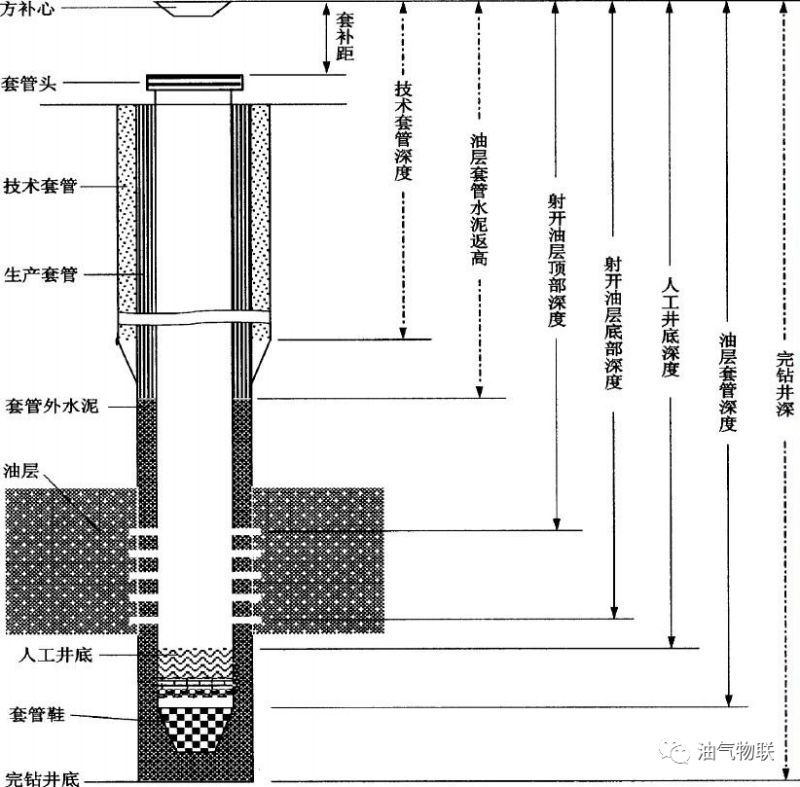

Ukwakhiwa komthombo:

1.Umqhubi

I-casing yokuqala esakhiweni somthombo eduze kodonga lwembobo evulekile ibizwa ngokuthi i-conduit. imisebenzi: ukuvikela ubuso obuseduze nekhanda lomthombo ekugezeni ekuqaleni kokumba, ukusungula ukujikeleza kodaka, ukuqondisa ithuluzi lokumba, ukuqinisekisa ukubhoboza okuqondile kwembobo, njll.

2. I-Surface casing

I-casing yesibili esakhiweni somthombo ibizwa ngokuthi i-surface casing. Umsebenzi uwukuvala ungqimba lwamanzi, ukuqinisa udonga lwedwala elingaphezulu elivulekile, ukuvikela umgodi nokufaka ipakethe.

3. Ibhokisi lebhokisi lobuchwepheshe

Ungqimba lwe-casing olufakwe ngaphakathi kwe-surface casing lubizwa ngokuthi i-technical casing. Umsebenzi uwukuvikela nokuvala ukwakheka okunzima nokuyinkimbinkimbi ngaphezu kwechibi ukuze kuqinisekiswe ukubhola okubushelelezi.

4. Isikhwama sesendlalelo samafutha

Ungqimba lokugcina lwe-casing emthonjeni kawoyela lubizwa ngokuthi i-oil layer casing, okubizwa ngokuthi i-casing. Umsebenzi wawo uwukuqinisa udonga lwemithombo yamanzi, ukuvala uwoyela, igesi kanye nezingqimba zamanzi, nokuqinisekisa ukukhiqizwa komthombo kawoyela isikhathi eside.

5. Ukufaka usimende

Ukufaka usimende kuyinqubo lapho udaka lukasimende lujovwa endaweni ephakathi kwebhokisi nodonga lomthombo. Umsebenzi wawo ukuqinisa udonga lomthombo, ukuvikela i-casing, nokuvala ungqimba ngalunye lwamafutha, igesi namanzi emthonjeni ukuze zingahlangani.

6. Umgodla kasimende

Ngemva kokuphothula zonke izinhlobo ze-casing kanye nokufaka usimende, isilinda sendandatho kasimende esiqinile siyakhiwa endaweni ye-annular phakathi kwe-casing kanye nodonga lomthombo, okubizwa ngokuthi indandatho kasimende. Umsebenzi wayo ukuvala ukubunjwa, ukuqinisa udonga lomthombo nokuvikela i-casing.

7. Master bushing

Lapho kubholwa i-rotary, ingxenye yepayipi le-kelly ibhajwe phakathi nendawo ejikajikayo ezungeza amathuluzi omgodi ophansi.

8. Ukujula kokumba okuphelele

Ukujula kokumba kokuphothula kubhekisela ekuphakameni ukusuka phansi kwembobo evulekile kuya phezulu endaweni ephansi yetafula elijikelezayo.

9. Ukujula kwekesi

Ukujula kwe-Casing kubhekisela ekujuleni phakathi kwendawo engaphezulu yetafula elijikelezayo kanye nendawo yesicathulo se-casing sokubunjwa kwamafutha.

10. Isingezansi somthombo wokwenziwa

Indawo engaphezulu yomthombo kawoyela ehlala egodini ngemva kokuba usimende ubekwe engxenyeni engezansi yebhokisi. Ukujula kwembobo engaphansi kokwenziwa kuvezwa ukujula kwebanga ukusuka phezulu kwetafula elijikelezayo ukuya embobeni yokwenziwa engezansi.

11. Ukubuya kukasimende okuphezulu

Ukuphakama kukasimende kubuya esikhaleni se-annular phakathi kwe-casing kanye nomthombo. Ukujula kokubuya kwe-cement kufana nebanga phakathi kwendawo engaphezulu ye-turntable kanye ne-cement surface yesikhala se-annular.

12. Ipulaki likasimende

Ngemva kokuqinisa, ikholomu yesimende kusukela phansi komthombo oboshiwe kuze kube phansi komthombo wokwenziwa yipulaki ye-cement.

Isikhathi sokuthumela: Oct-07-2023

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141