Imikhiqizo

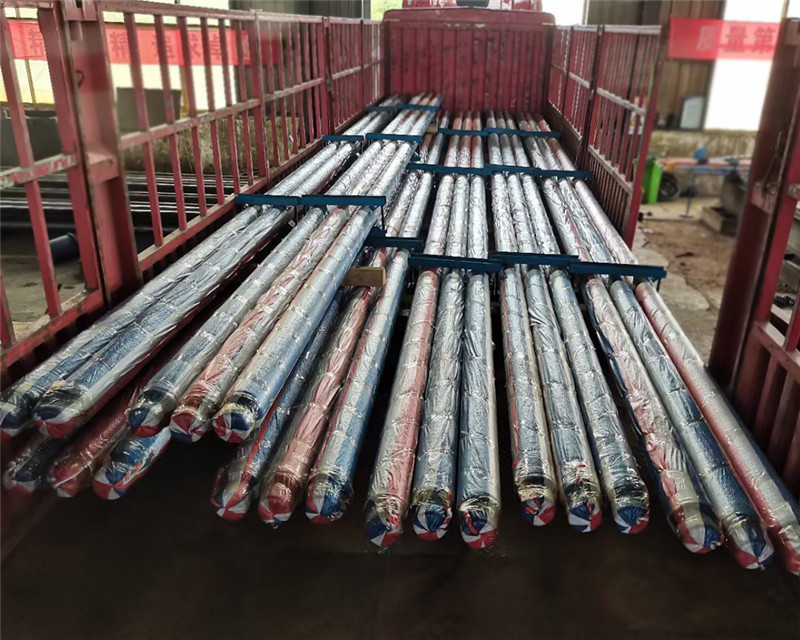

Amakholomu okuDrila okungewona Amagnetic nababhalisile

Ikholomu Yokubhola Okungeyona ekaMazibuthe

Ikhola Yokubhoboza Okungeyona I-Mag

I-Slick Non-Mag Drill Collar inikeza isisindo esidingekayo kubhithi, futhi ngeke iphazamise ikhono lokubhola eliqondisayo.

I-Spiral Non-Mag Drill Collar

I-Spiral Non-Mag Drill Collar iklanyelwe ukuvumela indawo enkulu yokugeleza yoketshezi lokumba, kuyilapho inikeza izinzuzo zensimbi engeyona imag ezinhlelweni eziyinkimbinkimbi zokumba.

I-Flex Non-Mag Drill Collar

I-Flex Non-Mag Drill Collar izacile futhi ivumelana nezimo kunekhola yokubhoboza evamile. Ikhono lazo lokwenza amajika erediyasi amafushane, ukugoba ukuze uthole ama-engeli okwakha aphezulu, futhi adlule kuma-doglegs awenza alungele ukusetshenziswa ekusetshenzisweni kokuqondisa nokuvundlile. Ekhiqizwe ngensimbi engeyona imag, le khola yokubhoboza ifaneleka kahle kumishini yezindlu ye-MWD.

Ukucaciswa Komkhiqizo

| Ukuxhumana | OD mm | ID mm | Ubude mm |

| I-NC23-31 | 79.4 | 31.8 | 9150 |

| I-NC26-35 | 88.9 | 38.1 | 9150 |

| I-NC31-41 | 104.8 | 50.8 | 9150 noma 9450 |

| NC35-47 | 120.7 | 50.8 | 915 noma 9450 |

| NC38-50 | 127.0 | 57.2 | 9150 noma 9450 |

| I-NC44-60 | 152.4 | 57.2 | 9150 noma 9450 |

| I-NC44-60 | 152.4 | 71.4 | 9150 noma 9450 |

| I-NC44-62 | 158.8 | 57.2 | 9150 noma 9450 |

| I-NC46-62 | 158.8 | 71.4 | 9150 noma 9450 |

| I-NC46-65 | 165.1 | 57.2 | 9150 noma 9450 |

| I-NC46-65 | 165.1 | 71.4 | 9150 noma 9450 |

| I-NC46-67 | 171.4 | 57.2 | 9150 noma 9450 |

| I-NC50-67 | 171.4 | 71.4 | 9150 noma 9450 |

| NC50-70 | 177.8 | 57.2 | 9150 noma 9450 |

| NC50-70 | 177.8 | 71.4 | 9150 noma 9450 |

| I-NC50-72 | 184.2 | 71.4 | 9150 noma 9450 |

| I-NC56-77 | 196.8 | 71.4 | 9150 noma 9450 |

| I-NC56-80 | 203.2 | 71.4 | 9150 noma 9450 |

| 6 5/8REG | 209.6 | 71.4 | 9150 noma 9450 |

| I-NC61-90 | 228.6 | 71.4 | 9150 noma 9450 |

| 7 5/8REG | 241.3 | 76.2 | 9150 noma 9450 |

| I-NC70-97 | 247.6 | 76.2 | 9150 noma 9450 |

| I-NC70-100 | 254.0 | 76.2 | 9150 noma 9450 |

| 8 5/8REG | 279.4 | 76.2 | 9150 noma 9450 |

I-Non Magnetic Stabilizer

I-integral non magnetic stabilizer yenziwe nge-forging eyodwa eqinile yensimbi engenazibuthe. Okubalulekile ukuhlanzeka okuphezulu kwe-Chromium Manganese Austenitic insimbi engagqwali.

Ukuhlolwa kwe-Ultrasonic kanye nokuhlolwa kwe-MPI kwenziwa ekufogeni ngakunye ngobude bayo obugcwele kanye nesigaba, ngemva komshini onzima ngokwe-API Spec 71. Izitifiketi zokuhlola ze-Mill ezihlanganisa izakhiwo zemishini, ukuhlaziya amakhemikhali, izakhiwo kazibuthe kanye nokuhlolwa kunikezwa zonke iziqinisi.

Sinamandla okukhiqiza i-Non Magnetic Stabilizer kuze kufike ku-Crown OD 26''

Ukucaciswa Komkhiqizo

| Amandla Okuqina | Isivuno Amandla | Ukuqina | I-Magnetic Permeability | |

| imiz. | imiz. | imiz. | MAX | Isilinganiso |

| 120KSI | 100KSI | 285HB | 1.01 | 1005 |

I-Non Magnetic MWD Sub

I-Non Magnetic MWD Sub yenziwe nge-Chromium Manganese Austenitic insimbi engagqwali, ipayipi elicindezelayo lokumelana nengcindezi lenziwa ngezinto ezingezona zokufaka i-MWD impulser ngaphakathi naphakathi kokunye. I-Non Magnetic MWD Sub isetshenziswe kabanzi yizinkampani zokumba eziqondisayo zasekhaya nezamazwe ngamazwe.

Konke ukuxhumeka kwenziwa ngomshini ngokusho kwe-API Spec.7-2 futhi izimpande zentambo zisebenza ngokubandayo futhi zihlanganiswe ne-API thread compound futhi ifakwe abavikeli.

Ukucaciswa Komkhiqizo

| Ububanzi (mm) | Ububanzi bangaphakathi (mm) | Ubude bobhore bangaphakathi (mm) | Isiphetho esiphansi indawo yokuvula (mm) | Umlenze ophelele (mm) |

| 121 | 88.2 | 1590 | 65 | 2500 |

| 172 | 111.5 | 1316 | 83 | 2073 |

| 175 | 127.4 | 1280 | 76 | 1690 |

| 203 | 127 | 1406 | 83 | 2048 |

I-LANDRILL I-Non Magnetic Materials indinganiso

Izici Ezingezona Zezibuthe:

I-Relative Permeability: Max 1.005

I-Hot Spot / I-Field Gradient: MAX ±0.05μT

Ukwelashwa Okukhethekile ku-ID: I-Roller Burnishing

Ngemuva kokushiswa kwe-roller, ungqimba olucindezelayo luba khona, izinzuzo ngale ndlela elandelayo:

Khulisa izakhiwo ezimelana nokugqwala, Khulisa ubulukhuni bobuso be-bore bufike ku-HB400, Khulisa ukuphela kwendawo yokubhoboza ukuya ku-Ra≤3.2 μm, Ukuhlolwa nokuhlolwa okwenziwa kubha ngayinye ngesikhathi sokukhiqizwa kwezingxenye ze-NMDC, Stabilizer ne-MWD.

Ukubunjwa Kwekhemikhali, Ukuhlolwa Kokuqina, Ukuhlolwa Komthelela, Ukuhlolwa Kokuqina, Ukuhlolwa Kwe-Metallographic (Usayizi Wokusanhlamvu), Ukuhlolwa Kokugqwala (Ngokuvumelana ne-ASTM A 262 Practice E), Ukuhlolwa kwe-Ultrasonic kubo bonke ubude bebha (Ngokusho kwe-ASTM A 388), I-maganetic ehlobene Ukuhlolwa kokuqina, Ukuhlolwa kwendawo eshisayo, ukuhlolwa kobukhulu, njll.

Izinketho zokwelapha zangaphandle ezikhethekile: Ukuchama kwesando, ukushiswa kwamarola, ukuchama kwesibhamu.

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141