Imikhiqizo

Ithuluzi lokugaya le-API 7-1 Casing Section

Iphrofayili yomkhiqizo

Ingxenye yokugaya iwuhlobo lwethuluzi lokuvula iwindi le-casing elihlanganisa ukusika kwe-casing kanye nemisebenzi yokugaya. Umshini wokugaya ugijima ku-casing kanye ne-BHA, bese usika i-casing endaweni emisiwe kuqala. Ngemuva kokuthi i-casing inqunywe ngokuphelele, izogaywa ngokuqondile kule ndawo. Ngemva kokufinyelela ekujuleni okuthile, umsebenzi wokuvula iwindi le-casing uyaqedwa. ingxenye yokugaya inezinzuzo zesakhiwo esilula, ukusebenza okulula ukuzenza ithuluzi lokuvula iwindi le-casing eliphumelelayo kakhulu.

Phakathi naleso sikhathi, umshini wokugaya ungakhama futhi ujove usimende ekusebenzeni kokulahla kahle, okungenza usimende uthintane ngokuqondile nokwakheka ebangeni elide ngaphakathi kwamadigri angu-360. Usimende ungangena ku-reservoir ngokusho kwe-porosity ekhona kanye nokuqhekeka kokwakheka, futhi umphumela wokuxhuma ungcono kakhulu kunowokukhama usimende ngemva kokubhobozwa.

Isimiso sokusebenza

Ngemuva kokuthi umshini wokugaya wehliselwe endaweni ebekiwe ku-casing kanye ne-BHA, qala itafula elijikelezayo, uvule iphampu, i-piston ethuluzini idudulelwa phansi ngenxa yokucindezela, ikhoni engezansi yepiston iphusha izindwani zokusika zivuleke futhi zilungise. umgodi ovulekile. Lapho izindwani zokusika zivuleka kububanzi obukhulu, ukulungiswa kwembobo evulekile kuphelile. Ngaphansi kwengcindezi yepompo eqhubekayo, i-blade ingavulwa futhi iphinde ibuyele umgodi ngokuqondile. Ngemuva kokuthi iphampu imisiwe, i-piston isethwe kabusha ngaphansi kokusebenza kwentwasahlobo futhi izindwani zokusika zizohoxiswa ngokuzenzakalelayo.

Izici zomkhiqizo

(1) Ukuklama komshini, isakhiwo esilula nokusebenza okulula

(2) Umfutho ophansi wokuqalisa kanye namandla amakhulu okusekela i-blade ayasiza ekusikeni kwe-casing;

(3) Ukwakhiwa kwentwasahlobo yamandla aphezulu kusiza ukuhoxisa ngokuzenzakalelayo umsiki ngemva kokusika;

(4) Idizayini ye-stop block nephinikhodi iyasiza ukuphoqelela ukuhlehla kwethuluzi;

(5) I-blade inokunwebeka okukhulu futhi ingasetshenziswa ku-casing efanayo enobukhulu obuhlukile bodonga;

(6) I-blade yenziwe ngekhwalithi ephezulu ye-tungsten carbide kanye nenqubo ye-Bake hughes efanayo yokushisela, enekhono eliphezulu lokusika kanye nempilo ende yesevisi.

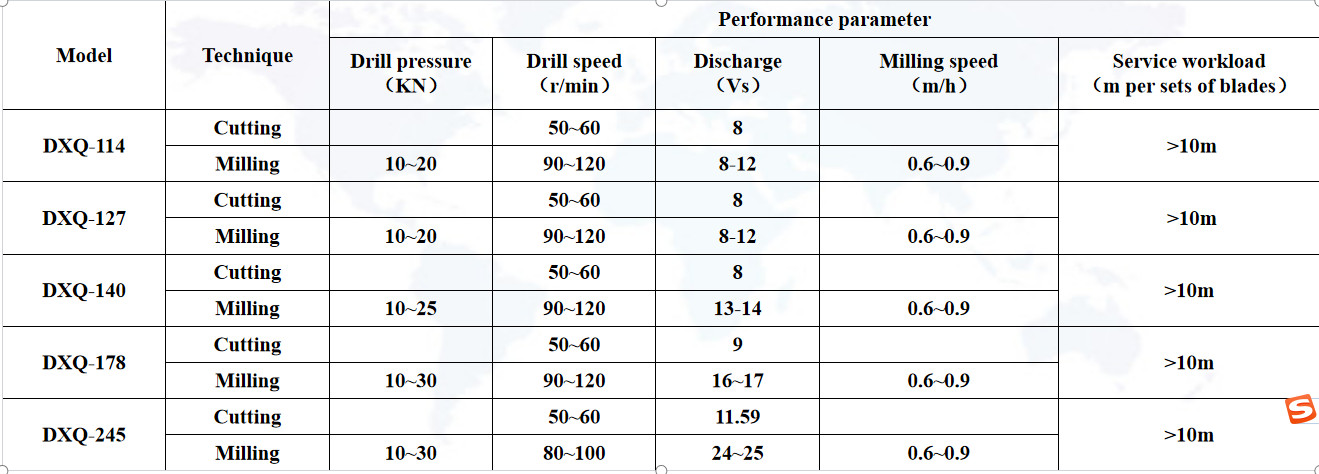

Ithebula lesigayo-Size

Amathuluzi afanayo - Isigayo se-taper sekilasi eliphezulu

Amathuluzi okugaya wonke enziwe nge-tungsten carbide alloy yekhwalithi ephezulu kanye nobuchwepheshe bokushisela obufanayo be-Baker Hughes. Inhloso yalolu chungechunge lwezigayo ukubuyisela ngokuphelele ukukhethwa kwempahla, ukwakheka kwesakhiwo kanye nenqubo yokushisela ka-Baker Hughes, ukuze kuzuzwe ikhwalithi yomkhiqizo efanayo ka-Baker Hughes.

2.Iphrofayili yomshini wokugaya wekilasi eliphezulu

ingakhiqiza isigayo se-taper esisezingeni eliphezulu esinobubanzi obungaphandle obungu-76 mm kuya ku-445 mm. Insimbi ye-alloy yekhwalithi ephezulu isetshenziswa njengomzimba oyinhloko, okuvumela ukucutshungulwa kwezimbobo zamanzi ezinosayizi omkhulu ukuze kuqinisekiswe ukukhishwa okushelelayo kwemfucumfucu yokugaya. Ngasikhathi sinye, ngokuya ngezidingo ezithile zamakhasimende, ukwakheka komkhiqizo kungaklanywa ukufeza ukusebenza okuhle kakhulu kokusetshenziswa.

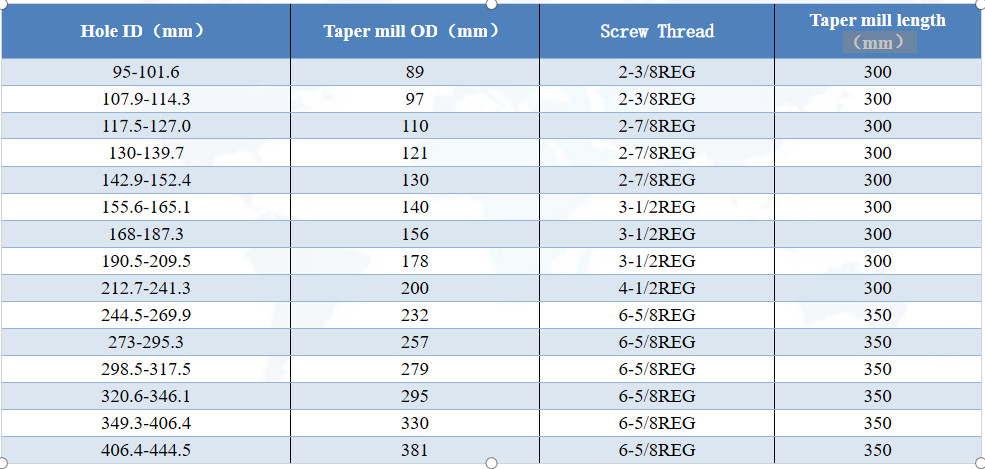

Ithebula le-3.Taper Mill-Size

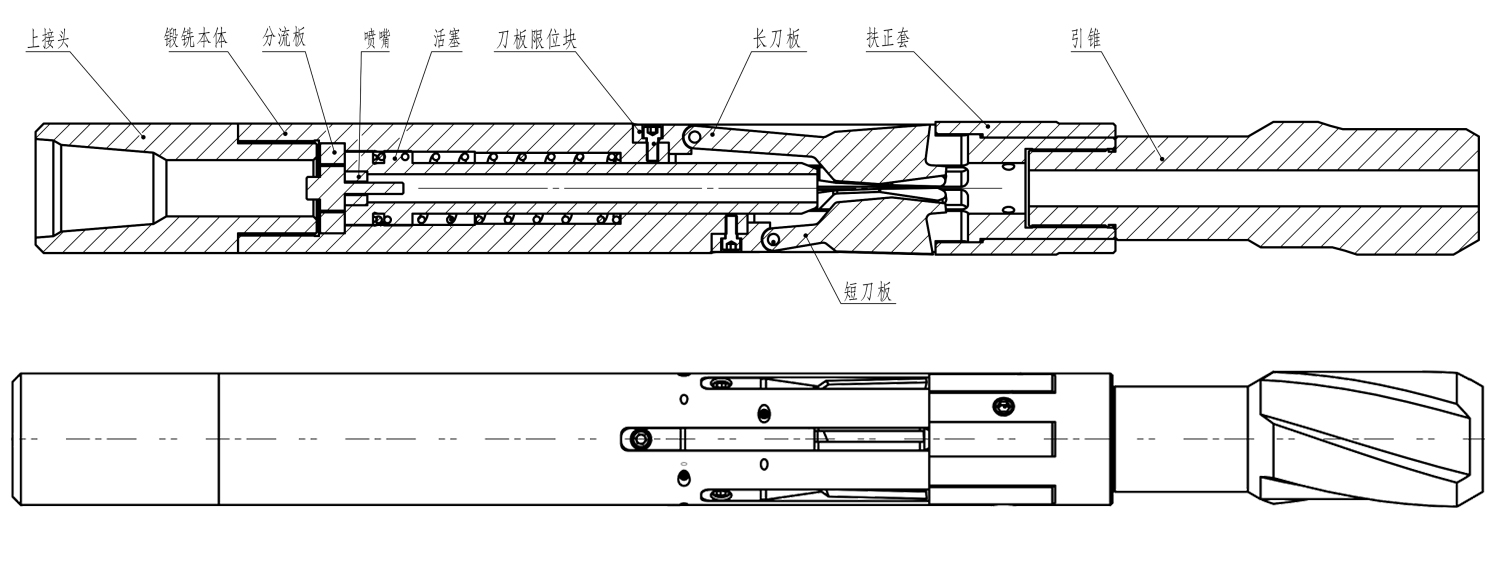

Isakhiwo somkhiqizo

1. Ingxenye yokugaya ngokuyinhloko ihlanganisa izingxenye ezilandelayo: ilunga eliphezulu, umzimba omkhulu, ipiston, umlomo wombhobho, ama-blades okusika kanye ne-guide cone, njll.

III.Izinzuzo zobuchwepheshe ze-Petrozhr section mill

1.Ikhiqizwe ngekhwalithi ephezulu ye-tungsten carbide

Izingxenye zokugaya izingxenye ezikhiqizwe yinkampani yethu zinezinzuzo ezilandelayo:

(1) Ukugaywa nokusika kuyashesha ukwedlula ama-blade ajwayelekile;

(2) Yehlisa ingcindezi yokumba edingekayo ukuze usike;

(3) Izimpawu zamazinyo ziyalingana futhi azikho indawo yokunyathela ekhiqizwayo;

(4) Imfucumfucu ekhiqizwayo ifana kakhulu;

(5) Ukuqina kwempahla eluhlaza kuphakeme futhi isakhiwo sinengqondo. Lapho isebenza, igawula insimbi kunokugaya insimbi.

2.Ukuhlolwa kwezinto ezingavuthiwe okuqinile

I-tungsten carbide ekhethwe yinkampani yethu izothunyelwa esikhungweni sokuhlola sochwepheshe ukuze ihlolwe ngemva kokufika kweqoqo ngalinye.Ukuqinisekisa ukuthi ubulukhuni be-alloy nezinye izinkomba zihlangabezana nezidingo zokukhiqiza zenkampani.

3.Inqubo yokushisela ephelele

Siqasha owayengumshiseli omkhulu wakwa-Baker Hughes futhi sikhetha amathuluzi okushisela afanayo nezinto ezisizayo endaweni yokusebenzela ye-Baker Hughes ukuze sibone ukukhiqizwa kabusha kobuchwepheshe bokushisela be-Becker ngokuqhubekayo namathuluzi.

Ukuze kuncishiswe ukuwohloka kwamathuluzi ngenxa yezinguquko ezishisayo ngaphambi nangemva kokushisela, sisungula uhlelo lokufakwa kwe-welding ukuqinisekisa ukuzinza kwejometri yomkhiqizo nokusebenza kahle komsebenzi.

IV.Inqubo yokusebenza kwesigayo

Ukulungiswa kwe-Wellhole:

1. Lungisa i-casing. Lungisa i-downhole casing nge-taper mill noma i-casing shaper.

2. Ukuhlanza Kahle. Geza uwoyela ongahluziwe noma olunye uketshezi emthonjeni ngamanzi ahlanzekile.

3. Ukukhuhla i-casing noma i-wellbore. Ukuklwelwa kwamapayipi kanye nokukhukhuleka kuzokwenziwa nge-scraper evamile kanye nobubanzi be-drift ukuya kumamitha angu-20 ngaphansi kwendawo yokugaya.

4. Lungisa uketshezi lokugaya. Izakhiwo zayo ezihlukahlukene zingaqinisekisa umthamo ozinzile wokuthwala imfucumfucu yensimbi.

Ukuhlolwa kwaphansi:

1. Hlola ukwethembeka kwamathuluzi;

2. Ukuguqulwa kwengcindezi yepompo kuhlolwa lapho ama-blades okusika evuliwe, okunikeza isisekelo sokwahlulela ukuthi i-downhole casing inqunywe ngokuphelele.

Ukukhetha indawo yokugaya:

1. Usimende ngaphandle kwegobolondo lengxenye yokugaya kufanele ufakwe kahle usimende.

2. Gwema indawo lapho i-casing ine- dislocation kanye nokuguqulwa. Uma kukhona isikhundla esinjalo, ukusebenza kufanele kwenziwe 30-40m ngaphezu kwesikhundla.Futhi indawo yokuqala yokusebenza kokusika izoba ngu-1-3m ngaphezu kokuhlanganisa okuseduze.

3. Iphakethe kufanele ligcinwe ngaphansi kwe-shaft. Ngokuvamile, ubude bephakethe kufanele bube ngaphezu kuka-100m.

Cutting casing:

① Ngemva kokuxhuma ithuluzi ku-BHA bese wehlela endaweni yokugaya, qala ithebula elijikelezayo ukuze unqume indawo yokuhlanganisa i-casing ngokuya ngerekhodi le-casing (logging), bese wehlisela ithuluzi libe cishe ku-1-3m ngaphezu kokuhlangana nebhuleki eliseduze. .

② Qala itafula elijikelezayo kuqala, ukhuphule ijubane elijikelezayo libe ngu-50-60r / min, qala iphampu, kancane kancane wandise ukufuduka, ukuze umfutho wepompo ukhule. Ngalesi sikhathi, ingcindezi yepompo ikhuphuka isuka encane iye enkulu, kancane kancane ikhula ibe ngu-10-12mpa.

③ Qhubeka nokusika i-casing for 20-45min. Lapho ukucindezela kwepompo kwehla ngokuzumayo ngo-2-5mpa, i-casing iyanqunywa. Ukuze wenze umzimba wokusika uvule ngokugcwele, gcina indawo yokusika kulesi sikhundla i-30min ngemuva kokusika, futhi kancane kancane wandise ukufuduka ukuze uqinisekise ukwakheka okuphelele kokuphuka.

Isikhwama sokugaya:

I-WOB inganyuswa kancane kancane ngemva kokunqunywa kwebhokisi. okulawulwa phakathi kwe-10-25kn, isivinini se-rotary sikhuphukela ku-80-120r / min, futhi ingcindezi yepompo ilawulwa ngaphakathi kwe-10MPa ukuqinisekisa ukuthi ukufuduka okujikelezayo kungathwala imfucumfucu yensimbi. Uma ingxenye ngayinye icishe ibe ngu-0.5m, ingabholwa i-1m ukuze ivuselelwe kabusha futhi ijikelezwe, ukuze kube lula udoti wensimbi ogaywe kusukela esigabeni ukuze ubuye kahle nge-annulus. Ngemuva kwemijikelezo engu-1-2, phinda uphinde uqhubeke nokufoja nokugaya.

[Enqubeni, kuyadingeka ukulungisa kahle ukusebenza kodaka ngenkathi kukhulisa ukufuduka; ngesikhathi esifanayo, hambisa kahle ithuluzi lokumba futhi ulungise ukujikeleza ukuze wenze izinsimbi zensimbi zibuyele ngokugcwele futhi uvimbele ukunqwabelana kwemfucumfucu]

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141