Imikhiqizo

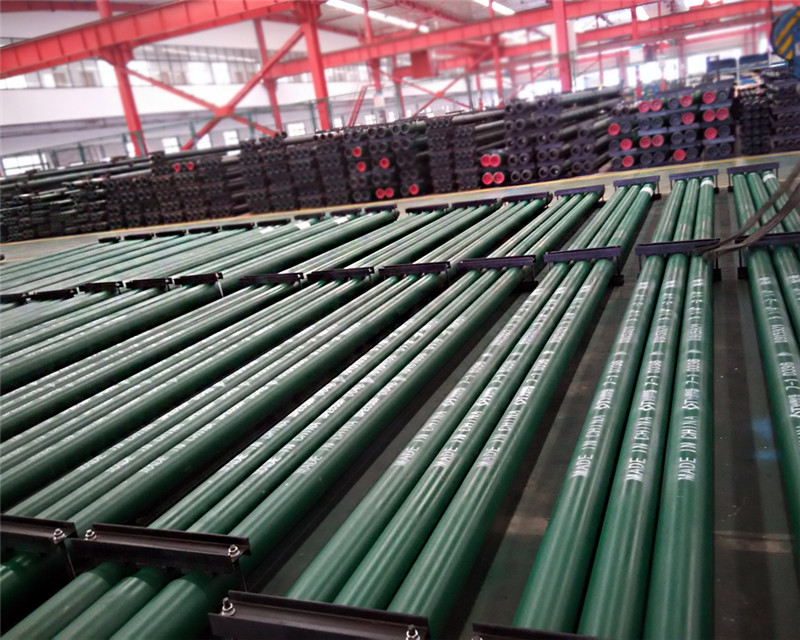

I-API 7-1 4145&Non-mag Drill Collar

Incazelo Yomkhiqizo

Ikhola yokubhoboza evamile iyisiphambano esiyindilinga, isikhungo sinembobo yamanzi, ukujiya kodonga kukhudlwana, umlomo wombhobho uncane, isisindo seyunithi ngayinye sikhulu kunosayizi wepayipi lokubhoboza cishe izikhathi ezi-4- 5 . i-drill collar iwukucubungula intambo ngqo emzimbeni wepayipi , kodwa amanye awo aphinde asebenzise ilunga elishintshiwe.

I-Spiral drill collar iwuhlobo lwethuluzi lokumba i-petroleum .Lolu hlobo lwekhola yokubhoboza luyakwazi ukuvimbela ukuboshwa kokucindezela okuhlukile kwamathuluzi ngesikhathi sokumba.Ama-Spiral grooves azokwenza udaka lugeleze ngokukhululekile ekholini yokubhoboza ukuze kusetshenziswe ukucindezela kwebhalansi ukuvimbela ukwakheka kwesithiyo ukuze kuvinjwe ngempumelelo ukuminyana kwengcindezi ehlukile.Indawo yokuxhumana emelene nodonga lomthombo ingasikwa ukuze kuncishiswe ngempumelelo amathuba okwenza ukuvinjelwa kokucindezela okuhlukile.Ama-Spiral grooves azokwenza udaka lugeleze ngokukhululekile ekholini yokubhoboza ukuze kusetshenziswe ukucindezela kwebhalansi ukuvimbela ukwakheka kwesithiyo ukuze kuvinjwe ngempumelelo ukuminyana kwengcindezi ehlukile.Indawo yokuxhumana emelene nodonga lomthombo ingasikwa ukuze kuncishiswe ngempumelelo amathuba okwenza ukuvinjelwa kokucindezela okuhlukile.Isisindo se-spiral drill collar singaphansi ngo-4-6% kunekholola yokubhola eyindilinga.

I-Non-Magnetic Drill Collar: Amakholomu okuDrila okungewona uzibuthe enziwe ngezinto zekhola zokubhola ezingezona uzibuthe ezinamandla aphansi ngokuhlanganisa ukuhlaziya okuphathelene namakhemikhali kanye nenqubo yokubumba isando ejikelezayo enekhono elihle lomshini lokungena kazibuthe.singahlinzeka ngobude obusuka ku-10 kuya ku-42 futhi ububanzi obungaphandle ukusuka ku-31/8" kuya ku-11'.

Ukucaciswa Komkhiqizo

| Usayizi | I-OD(mm) | I-ID(mm) | Ikhodi | Uchungechunge | Ubude(mm) | Isisindo(kg) |

| 3-1/8 | 79.4 | 31.8(1-1/4) | I-NC23-31 | NC23 | 9140 | 298 |

| 3-1/2 | 88.9 | 38.1(1-1/2) | I-NC26-35 | NC26 | 9140 | 364 |

| 4-1/8 | 104.8 | 50.8(2) | I-NC31-41 | NC31 | 9140/9450 | 474/490 |

| 4-3/4 | 120.6 | 50.8(2) | NC35-47 | NC35 | 9140/9450 | 674/697 |

| 5 | 127 | 57.2(2-1/4) | NC38-50 | NC38 | 9140/9450 | 725/749 |

| 6 | 152.4 | 57.2(2-1/4) | I-NC44-60 | NC44 | 9140/9450 | 1125/1163 |

| 71.4(2-13/16) | I-NC44-60 | 9140/9450 | 1022/1056 | |||

| 6-1/4 | 158.8 | 57.2(2-1/4) | I-NC44-62 | NC44 | 9140/9450 | 1237/1279 |

| 71.4(2-13/16) | I-NC46-62 | 9140/9450 | 1134/1172 | |||

| 6-1/2 | 165.1 | 57.2(2-1/4) | I-NC46-65 | NC46 | 9140/9450 | 1352/1398 |

| 71.4(2-13/16) | I-NC46-65 | NC50 | 9140/9450 | 1249/1291 | ||

| 6-3/4 | 171.4 | 57.2(2-1/4) | I-NC46-67 | NC46 | 9140/9450 | 1471/1521 |

| 7 | 177.8 | 57.2(2-1/4) | NC50-70 | NC50 | 9140/9450 | 1597/1651 |

| 71.4(2-13/16) | NC50-70 | 9140/9450 | 1494/1545 | |||

| 7-1/4 | 184.2 | 71.4(2-13/16) | I-NC50-72 | NC50 | 9140/9450 | 1625/1680 |

| 7-3/4 | 196.8 | 71.4(2-13/16) | I-NC56-77 | NC56 | 9140/9450 | 1895/1960 |

| 8 | 203.2 | 71.4(2-13/16) | I-NC56-80 | NC56/6-5/8REG | 9140/9450 | 2040/2109 |

| 8-1/4 | 209.6 | 71.4(2-13/16) | 6-5/8REG | 6-5/8REG | 9140/9450 | 2188/2263 |

| 9 | 228.6 | 71.4(2-13/16) | I-NC61-90 | NC61 | 9140/9450 | 2658/2748 |

| 9-1/2 | 241.3 | 76.2(2-13/16) | 7-5/8REG | 7-5/8REG | 9140/9450 | 2954/3054 |

| 9-3/4 | 247.6 | 76.2(3) | I-NC70-97 | NC70 | 9140/9450 | 3127/3234 |

| 10 | 254 | 76.2(3) | I-NC70-100 | NC70 | 9140/9450 | 3308/3421 |

| 11 | 279.4 | 76.2(3) | 8-5/8REG | 8-5/8REG | 9140/9450 | 4072/4210 |

Izici Nezinzuzo

Ububanzi bokuqina obungu-285 kuya ku-341 BHN kanye nevelu yomthelela we-Charpy engu-40 ft-lbs kuqinisekisiwe ngokusatshalaliswa ngokulinganayo kwamaphoyinti angu-16 kunoma yiziphi izingxenye eziphambanayo ekamelweni lokushisa;

Izixhumi zimbozwa nge-phosphate ngemva komshini ukuze kuvikelwe imicu ezintweni ezonakalisayo futhi kuvinjwe ukugabha lapho kwakheka okokuqala;

Izimpande zomucu ziyabanda ekuxhumekeni kwe-API;

Izivikeli zentambo yensimbi ecindezelwe zihlinzekwa kuwo wonke amakholomu okubhoboza afakwe ukuxhumana okujwayelekile.

Izinketho

I-Stress groove.Izici zokukhulula ingcindezi kuphinikhodi ye-API noxhumo lwebhokisi ukuze kuncishiswe ukugxilwa kwengcindezi ephezulu ngaleyo ndlela kuthuthukiswe amandla okugoba ezindaweni zokuxhuma.

Ukugoqa okubandayo kwezimpande zomucu kubonise imiphumela enenzuzo yokuthuthukisa ukumelana nokukhathala koxhumano ngokunciphisa ukuqaliswa kokuqhekeka.

I-Hardbanding.I-Hardbanding ezindaweni ezingaphansi nangaphezulu kwekhefu lokushelela noma ehlombe lephini kwandisa impilo yesevisi yamakholola okubhoboza.Ingasetshenziswa futhi ekucushweni okucaciswe amakhasimende.I-Hardbanding ezindaweni ezingaphansi nangaphezulu kwekhefu lokushelela noma ehlombe lephini kwandisa impilo yesevisi yamakholola okubhoboza.Ingasetshenziswa futhi ekucushweni okucaciswe amakhasimende.

Izinsika zokushelela kanye nekheshi.Irediyasi engaphezulu yekhefu lekheshi iyagoqwa ukuze kuthuthukiswe impilo yomkhiqizo.Izinti zokushelela nezikheshi zenziwa ngomshini ngokuhambisana ne-API Spec 7-1.

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China

Igumbi 703 Isakhiwo B, isikhungo saseGreenland, indawo yokuthuthukiswa kwe-Hi-tech Xi'an, China 86-13609153141

86-13609153141